Bambu

Jan 01, 2013

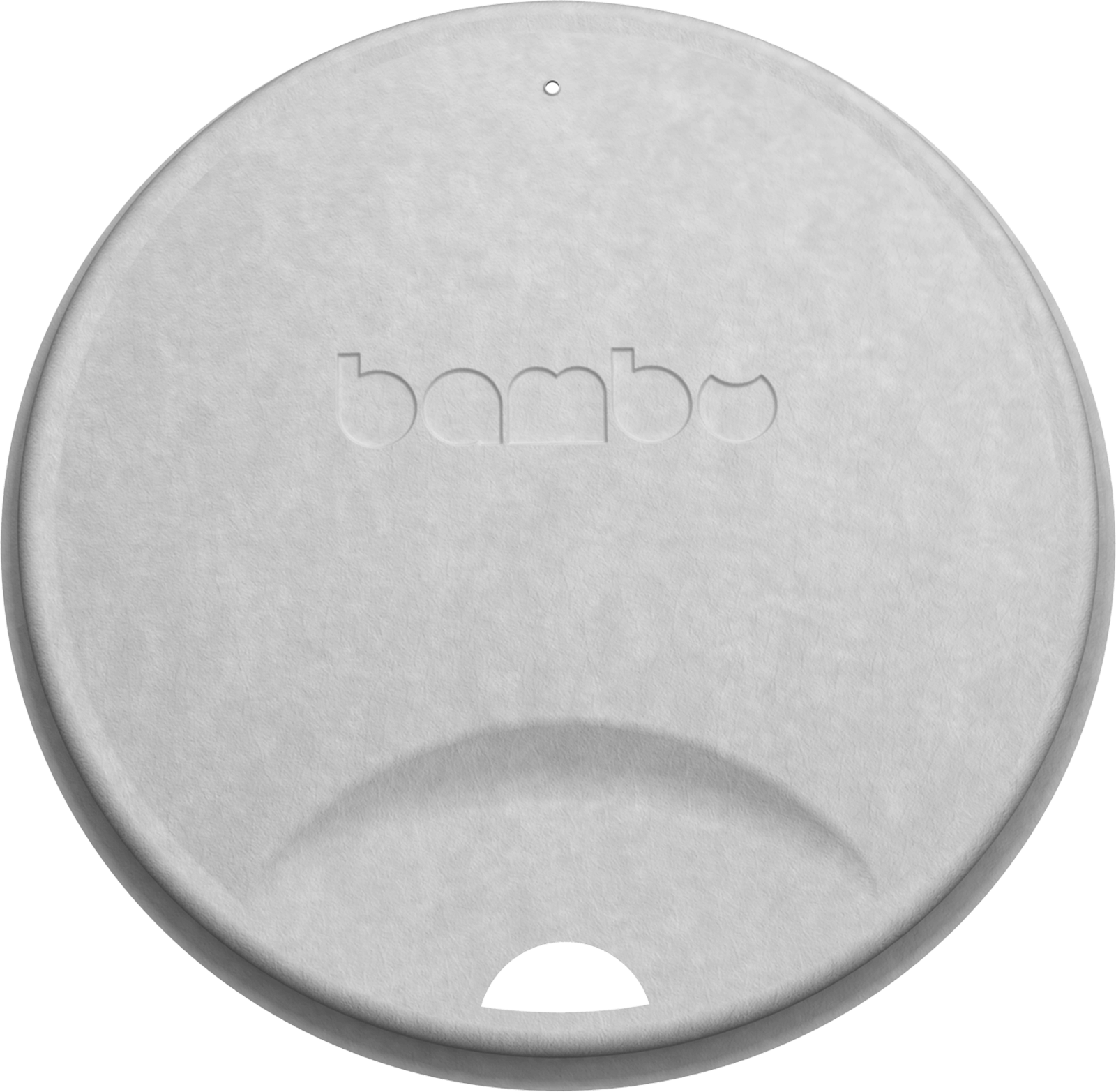

Our present methods of production, consumption and disposal are destroying our global life-support system. The search for alternatives, more eco-friendly materials such as paper in applications like packaging is increasing. Whether paper is better than plastic is a complex issue but one thing for certain is that paper unlike most plastics, is derived from a renewable feedstock. Considering the mass produced nature of coffee lids and that the current solution is inert to degradation, the purpose of this project was simply to replace the petroleum-based coffee lid with a new version in paper. Bambu is a new take-away coffee lid made from a uniquely durable and stretchable paper material.

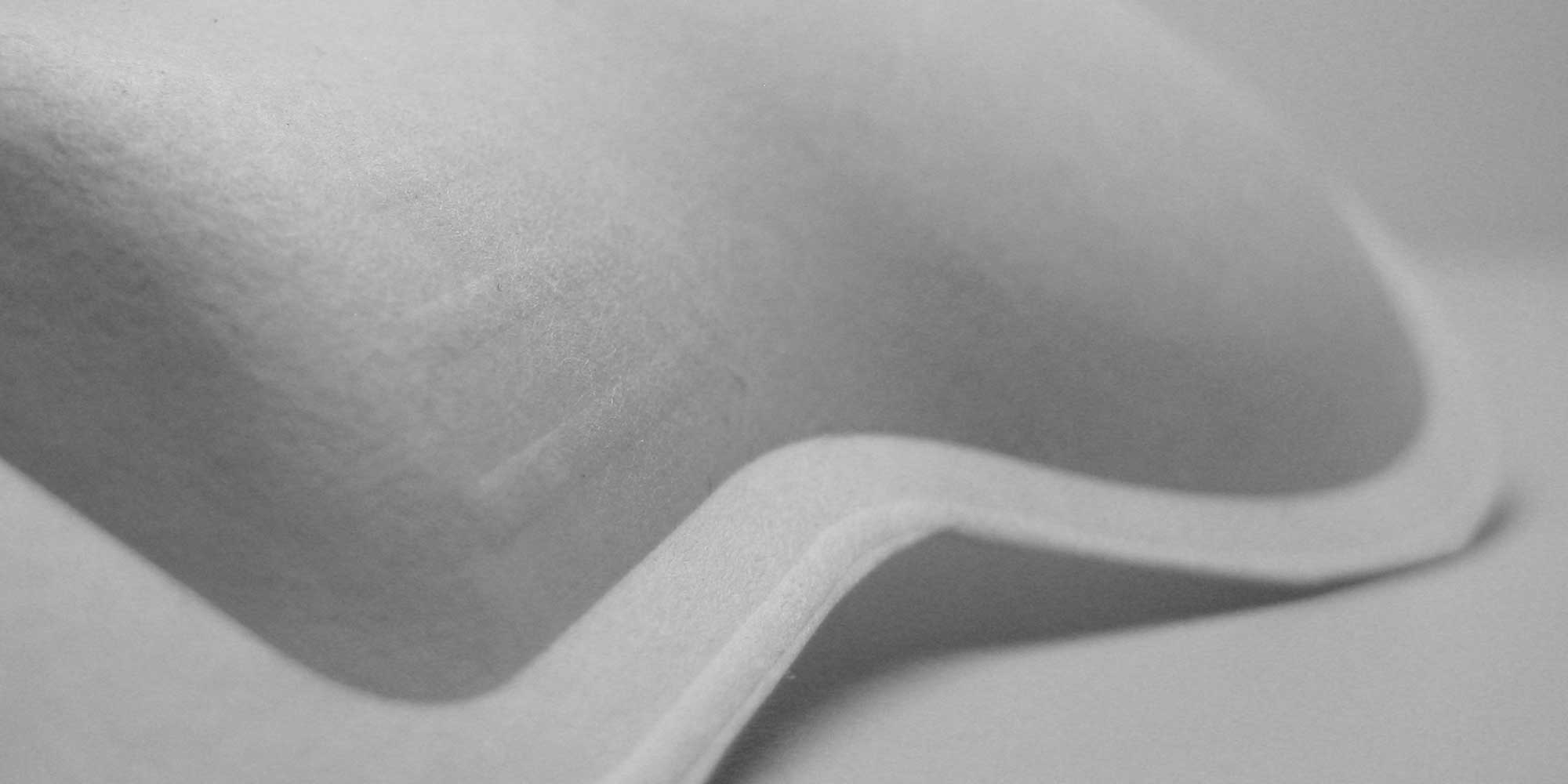

A unique paper material

The material used for the lid is a durable, resistant and highly stretchable paper, offering completely new opportunities when it comes to packaging design. Its fibres can be stretched out to form 3-dimensional shapes or to create fine detailed embossings.

Material guideline

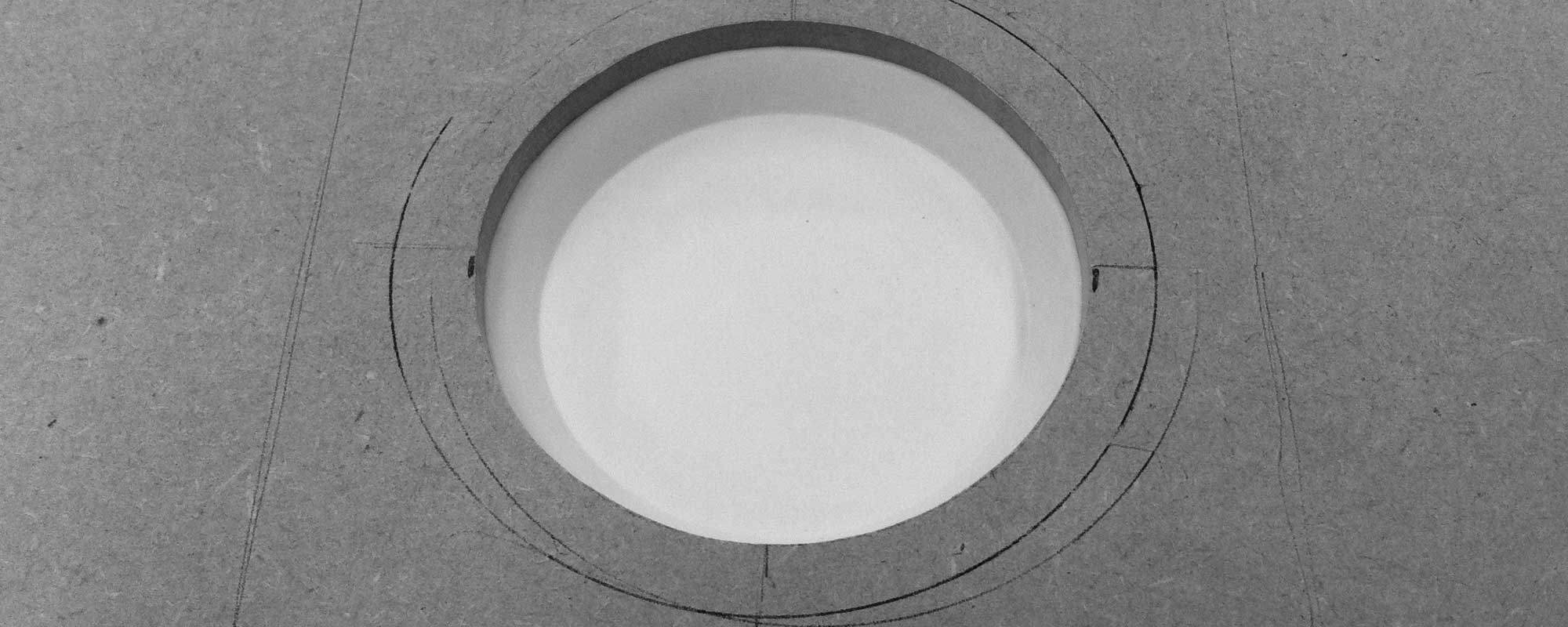

As the design process started, it was key to experiment with the material, to explore its strength as well as to create a guideline on how far it can be pushed. To do so, dimensions of a regular plastic lid was used as a reference and set as a target where two types of parameters were defined: form depth and side angle. A series of tests were then performed in which the paper was vacuum formed and then pressed into different combinations.

Tools were made for the paper to be vacuum formed into a bubble, then pressed to finally define what is and what is not possible to achieve.

Material guideline

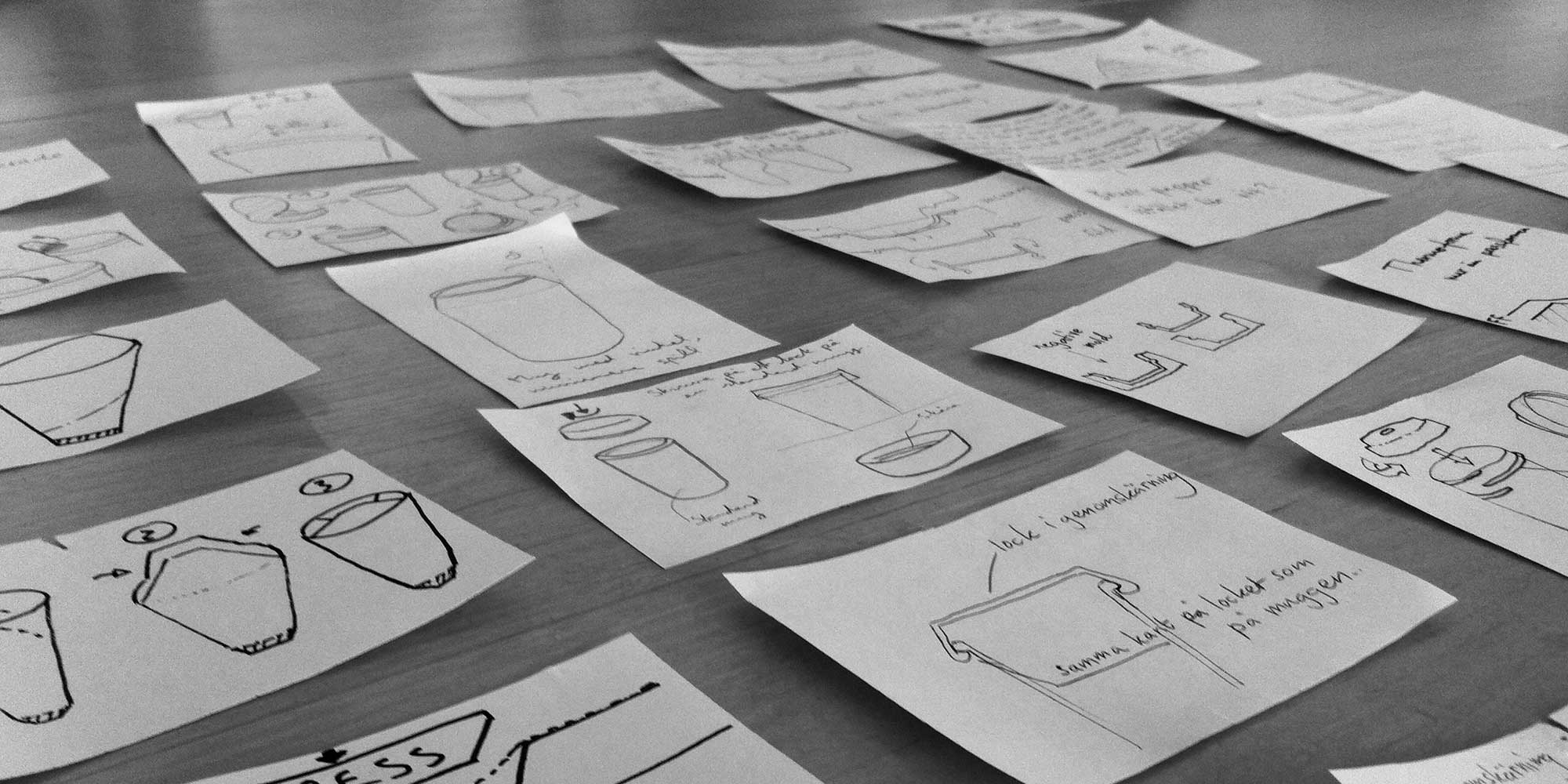

In parallel with the accumulated knowledge from research, an early idea generation was made. It resulted in three design tracks, the first one called “Origami” that is a cup with a folding mechanism, making a separate lid unnecessary. A second track called “Combo” that is a new lid and cup that fits exclusively. And finally, a third track called “Solo” that is a conventional idea of designing a lid for a standard take-away paper cup. The last one was selected for a better market strategy and from a technical standpoint it was considered to be the most feasible one.

Design features

The first feature to be defined was the drink area, that includes the opening and its surrounding surface. To start, a wide range of mockups were sculptured by attaching a piece of styrofoam to the bottom half of a plastic lid. A user assessment was then done where participants evaluated three versions of the lid. The result is a drink area with smooth curvatures and an opening having the same size as regular plastic lids.

Mockups were created for a design refinement. The last one was selected for its neutral design, better branding and manufacturing ability.

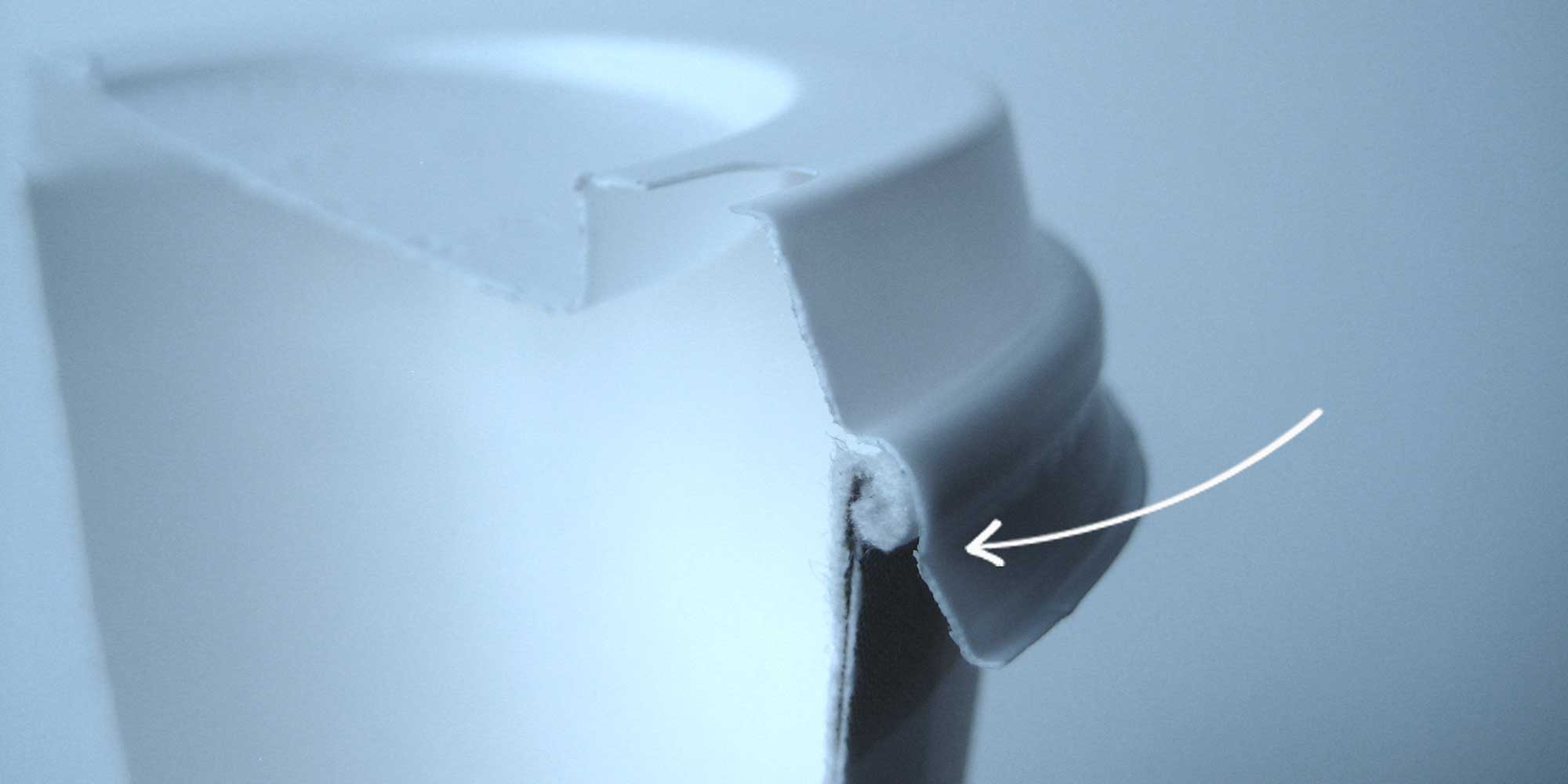

Attachment of the lid

The next feature is the most challenging and critical one, the juncture between the lid and cup. By exploring existing lids on the market, the large majority share this same idea of a groove that snaps under the top edge of the cup. This phase required a lot of time, to figure out the right manufacturing process that can make it all work, considering the limitations of the material.

Manufacturing

It was a breakthrough traveling to Denmark visiting a company that very soon became a partner for prototyping. Specialised in thermoforming and press forming, some critical facts were acquired such as “it is only possible to work with vertical movements” when forming the lid.

The idea that emerged was to use the vacuum and air pressure to form the negative groove while both molds were closed.

Prototyping

The previously mentioned idea is a theory on how to form a negative groove that is crucial for the lid to snap onto a cup. Three prototypes were created in CAD and milled in aluminum with CNC technology.

The result is a well-defined lid with a side groove that proved to be more and more distinct. Here is a short video from the inside of the Kiefel production line.

Bambu against competition

Compared to a regular plastic lid in polystyrene, bambu emits 62% less CO2. However it is 25% more expensive, but on the other hand costs for waste management may be reduced. On top of that, an evaluation of the prototype revealed an early indication that the product is well received. The aesthetics and material feel proved to be in favor of bambu.

Conclusion

Every year, 70 billion take-away coffee cups are sold in Europe and USA. If bambu can make a positive change in this product category, the implications would be huge; ecologically, economically and socially.

There is still some way to go before a finished prototype is realised. This is not the end, this is a continuation of a work with passion to develop a market-ready product. May bambu be a humble contribution to a world with less trash.